1. Whether building a wall in the garden, laying a

patio, adding an extension, converting a garage into an office or simply making a

concrete path, one question is certain to crop up "how much do I

need?".

It is one of the most important questions and one that tends to

cause the most confusion when trying to work out the answer. If you are

planning a garden wall, for example, you will know the length and the height,

but how many bricks are necessary? Even more important, how many bags of sand

and cement will you require? There is nothing more frustrating than starting a

job only to run out of materials part way through!

Brick

sizes vary slightly because of the way they are made but for ease of

calculation the size of one brick is taken as 215mm x 102.5mm x 65mm and for

normal brickwork the joint between the bricks bath vertical and horizontal is

10mm.

When

deciding how many bricks are required, the thickness of the mortar joint is

included into the calculations, making the measurement of the brick 225mm x

102.5mm x 75mm. By adding the mortar joint thickness any slight variations in

size for the bricks are taken into account.

When

determining how many bricks are required you should first work out the area of

the brick work as follows:- Length of wall say 4m, height of wall say 0.5m,

multiply the two figures together, 4m

x 0.5m =

2 square metres. Square metres are often written as ‘m2’ or sq.m’. For

an easy rule of thumb guide, you should

allow

60 bricks per square metre for the building of a single skin wall. This

is known as a half brick wall. The style is known as Stretcher Bond with only

the long ‘Stretcher’ faces of the bricks visible.

For example a 2 square

metre wall, you will need to multiply 2 (area of brickwork) x 60 (number of

bricks per square metre) =

120 bricks. If

you intend constructing a one brick thick solid wall, then you should allow for

119 bricks per square metre. So for a one brick thick solid wall you will need 2

(area of brickwork) x 119 number of bricks per square metre) = 238 bricks. The

visible ends of bricks are known as 'headers’.

These

figures do not allow for wastages or breakages, so it would be advisable

to add a few extras to the order to make certain you don't run short. Normally 10%

extra should be sufficient.

The

next question to be answered is how much mortar will I need?

To

find out how many bags of sand and cement you will need for example if you had a

wall 4 meters long and 0.5 meters high, and used 120 bricks, you need to divide

the total number of bricks (120) by 40 (coverage of one bag)

120

divided by 40 = 3, So 3 bags are required ( if your mortar mix

was 1:3 you should by 1 bag cement and 3 bags sand)

Concrete

blocks are much easier to calculate. Each block is 450 x 215 x 100. Ten blocks

will construct approximately 1 square meter of wall, with 1 bag of sand/cement

mix enough for 10 blocks.

back

to top

2. CHOOSING MORTAR MIXES FOR BRICKWORK

| Type

of Construction |

Proportion

of Cement / Building Sand |

| External

walls above DPC |

1

part cement : 5 parts sand |

| External

walls below DPC |

1

part cement : 4 - 5 parts sand |

| Internal

walls &inner leaf cavity walls |

1

part cement : 6 parts sand |

| Coping

stones and sills |

1

part cement : 3 parts sand |

| Parapets

and chimneys |

1

part cement : 4 - 5 parts sand |

| Retaining

walls |

1

part cement : 3 parts sand |

| External

free standing walls |

1

part cement : 4 - 5 parts sand |

| Manholes |

1

part cement : 4 - 5 parts sand |

back

to top

3. CHOOSING MORTAR MIXES FOR BLOCK WORK

| Type

of Construction |

Proportion

of Cement / Building Sand |

| External

walls above DPC |

1

part cement : 6 parts sand |

| External

walls below DPC |

1

part cement : 5 parts sand |

| Internal

walls |

1

part cement : 6 parts sand |

| Parapets |

1

part cement : 6 parts sand |

| External

free standing walls |

1

part cement : 5 parts sand |

| Manholes |

1

part cement : 5 parts sand |

back

to top

4. MEASURES TO CREATE CONCRETE

| Number

of bags of cement |

Number

of bags of ballast (50Kg) |

Amount

of Water in litres |

Produces

this amount of concrete... |

| 1 |

12 |

37 |

0.25

cubic meter |

| 2 |

24 |

74 |

0.5

cubic meter |

| 3 |

36 |

104 |

0.75cubic

meter |

| 4 |

48 |

150 |

1

cubic meter |

back

to top

5. CHOOSING MORTAR MIXES FOR RENDERING

| Background

material |

Proportion

of Cement / Building Sand |

| |

Undercoat

¦ Top coat |

| Low

suction bricks / blocks /stone |

1cement: 3 sharp sand

¦1cement: 5 sharp sand |

| Normal

suction bricks (clay etc) |

1cement: 5 sharp sand

¦1cement: 6 sharp sand |

back

to top

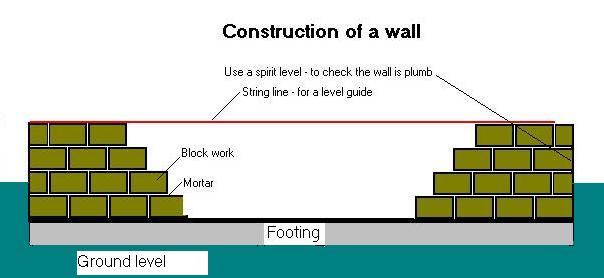

6. Right! you've sorted the materials, how do you

build it?

First, to build a brick wall outside, you must build a base (called a footing)

for the wall to stand on. Footings must be dug well into the ground (normally

about 700mm down). The footings need to be placed at least at this depth as the

ground temperature remains constant at this depth. If you are building an

extension to your house, it is important to ensure your footings are deep enough

prior to constructing anything!

Once you have dug your footings, pour concrete into the trench, (at least

600mm* wide and 250mm* inches deep for cavity walls) to provide a solid base to build your wall onto.

* these footings may need to be larger - depending on how high the wall is

to become (the example should be enough for a one story high wall).

The footings can either be filled with ready mix concrete from your local

concrete mixing company, or you can mix it yourself. To mix it yourself, mix 6

parts ballast with 1 part cement, add water until you have a pour-able mixture.

Allow the mix to set for 2 days minimum.

To build block or brickwork, you need to make a load of

'mortar' - see the table to choose the correct mixture. Remember to insert a DPC

(Damp Proof Course) about 30mm off of the floor, between the courses.

Starting from each end of your wall, build a small portion of the wall,

then

run a piece of string between what you have just built (this will give you a

plumb line to use as a guide to keep your wall straight). Build the wall between

the ends until you are up to the string, then build up the ends and move the

string higher. Repeat this process until your wall reaches the desired height.

Don't forget to keep a frequent check on the level of the wall with a spirit

level!!

back

to top

7. Construction of a wall - how to keep it level...

back

to top

8.

Different types of sand

Sand is graded by its size and

shape, and its important to get the right type of sand for the job (like

anything in life!)

Sharp Sand - A course and

gritty material, normally used with another aggregates for making concrete and

floor screeds.

Soft Sand - Known as

'builders sand'. It has smoother particals and is of a finer grade than sharp

sand. It is mixed with Cement to produce mortar, or render.

Course Aggregate - Course

gravel or crushed stone between 5mm to 20mm in size. It is used to form concrete

when mixed with sharp sand and cement

Ballast - Is a combined

'all in' aggregate, this is a mix of sharp sand and course aggregate, used for

making concrete.

back

to top |